At CT Mechanical, we know the importance of lean installation techniques for minimizing wasted materials, time and energy. That’s why we start off every project with a lean mindset to maximize your value from the minute we come onboard. Learn how we schedule out lean installations and see the difference for yourself.

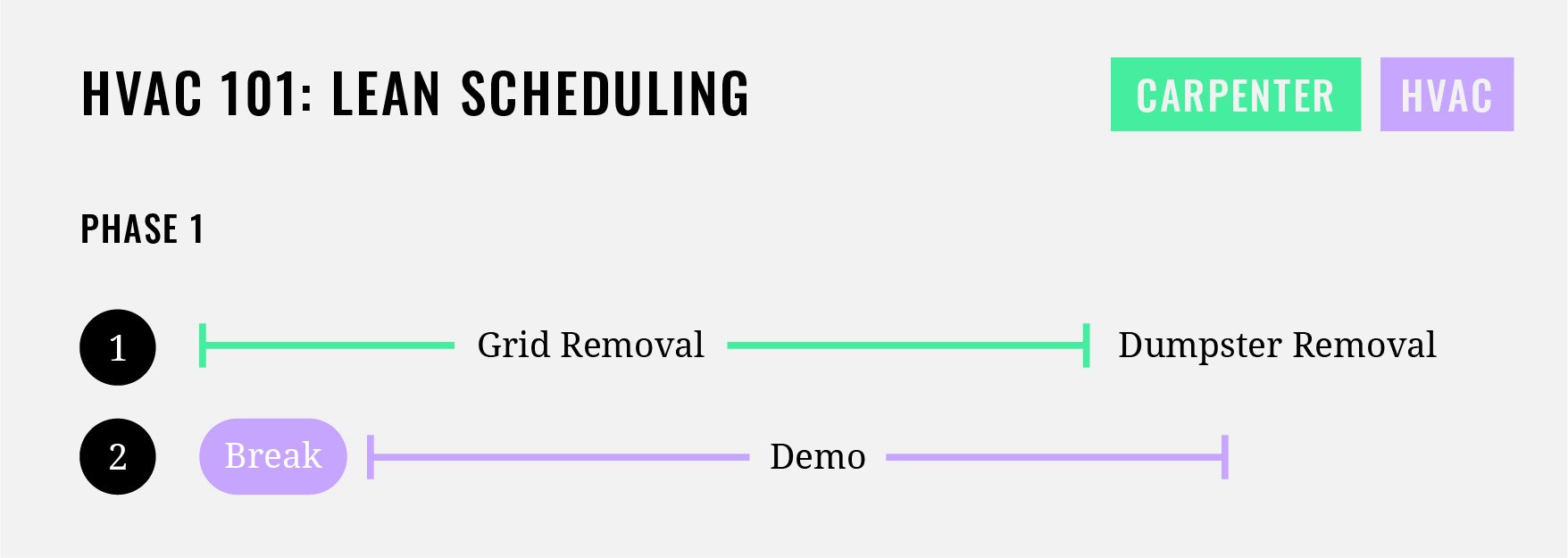

PHASE 1

- Carpenter removes the grid.

- HVAC begins approximately one day after the carpenter for every 2,000 sq. ft. of space. A two-woman crew can demo 10,000 sq. ft. per day while a two-man crew can only demo 5,000 sq. ft. per day (sorry not sorry boys).

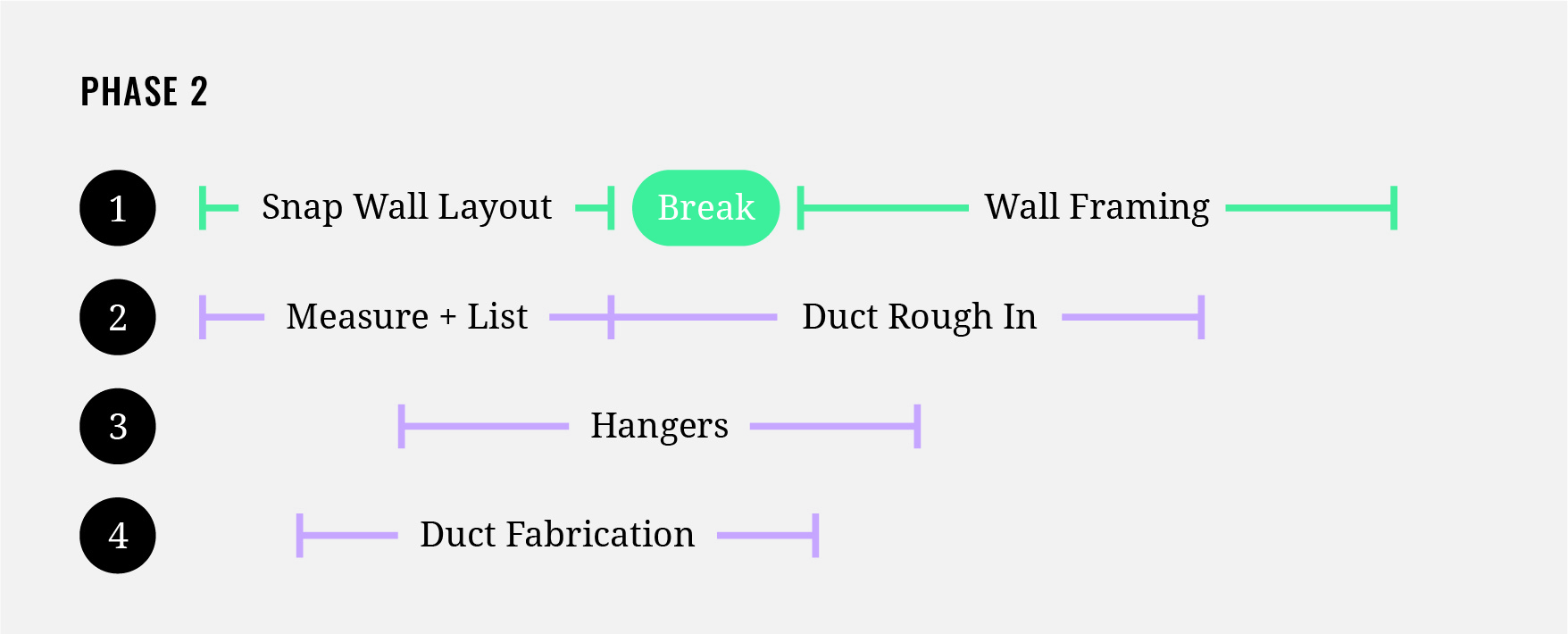

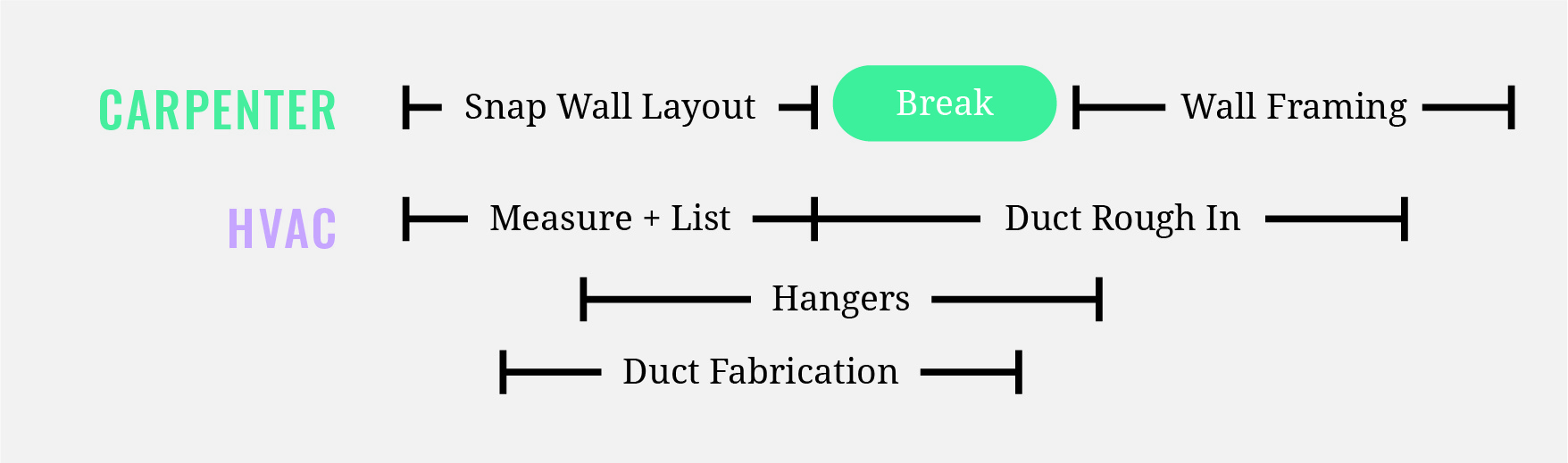

PHASE 2

- HVAC measures and lists one day before the carpenter’s snap wall layout. For every 2,500 sq. ft. of space, we need one day of measure and list time.

- Carpenter begins snap wall layout.

- HVAC begins hangers and duct fabrication.

- HVAC begins duct rough ins.

- Carpenter begins wall framing. For most projects under 50,000 sq. ft., we need four days for duct rough ins before wall framing.

PHASE 3

- Carpenter finishes ceiling framing and cutting openings.

- HVAC installs ceiling boots.

- Carpenter starts installing the grid. It’s key that all or most of the grid is finished when we return.

- HVAC returns to install the GRDs. We need one day of work for every 2,000 sq. ft. of space.

- Carpenter installs the ceiling pads.

- HVAC tops off the installation with any surface mount GRDs.

- HVAC tests and balances everything to ensure our installation is complete.

Call us today at 630.227.1700 to schedule your lean installation!